Dave bought this Suzuki GSX600F for £400 to participate in the Longest Day Challenge, but before it can cover 1000 miles in a day it needs a bit of work. Ok, a lot of work… Can he get it ready in time?

Words & photography: Dave Manning

Originally published in the August 2024 issue of Motorcycle Sport & Leisure. Catch up with part 1, part 2 & part 3.

Enjoy everything MSL by reading the monthly magazine, Subscribe here.

Tock tick, tick tock. Time scrolls past as Dave fights more issues…

Last month, I was worried that with six weeks to go I hadn’t even started the bike yet… shortly after I wrote that, Rob Bean had paid a visit and sorted the electrics, and I did indeed get it started. And it ran terribly, initially with a nasty rattle from the bottom end and, as the revs started to rise, getting a little quieter. The revs rose more, and a quick squirt of brake cleaner around the intake rubbers saw the revs rise further again, indicating that the inlet rubbers were cracked and letting in air. But worse, I glanced into the back of the airbox to see a lot of smoke whirling around. A lot. I pulled the breather hose off the rocker cover breather tower, and the amount of smoke issuing showed that there was lots of crankcase pressure from piston ring blow-by and/or valve stem seal issues. This engine was toast.

Clearly, the mileage on the speedo wasn’t reflective of the miles that the engine had covered.

Grumpily, I sat down on the garage floor in a sulk. And my eyes came to rest in the corner. On the spare engine from my Bandit race bike. The 600 Bandit was based on the GSX600F engine… While the spare race engine is a bit leaky (the usual Suzuki oil drain tubes at the front of the engine), it was a decent runner when it was in the Bandit. Right, engine swap time!

This should have been a really easy job. But remember how I mentioned the exhaust studs last month, and how they looked like they’d be a nightmare to remove? They were all so corroded that not a single one could be loosened with an allen key. Two did come free after hammering a Torx bit into the end, and the outer right-hand side one was cut in half using a hacksaw blade threaded through a little gap in the frame (which took about 40 minutes of sawing!). The remaining five all needed to have an allen socket MIG-welded to the end, but not one of them stripped a thread or snapped in the head! Not that I was bothered if they had, what with the engine effectively being scrap…

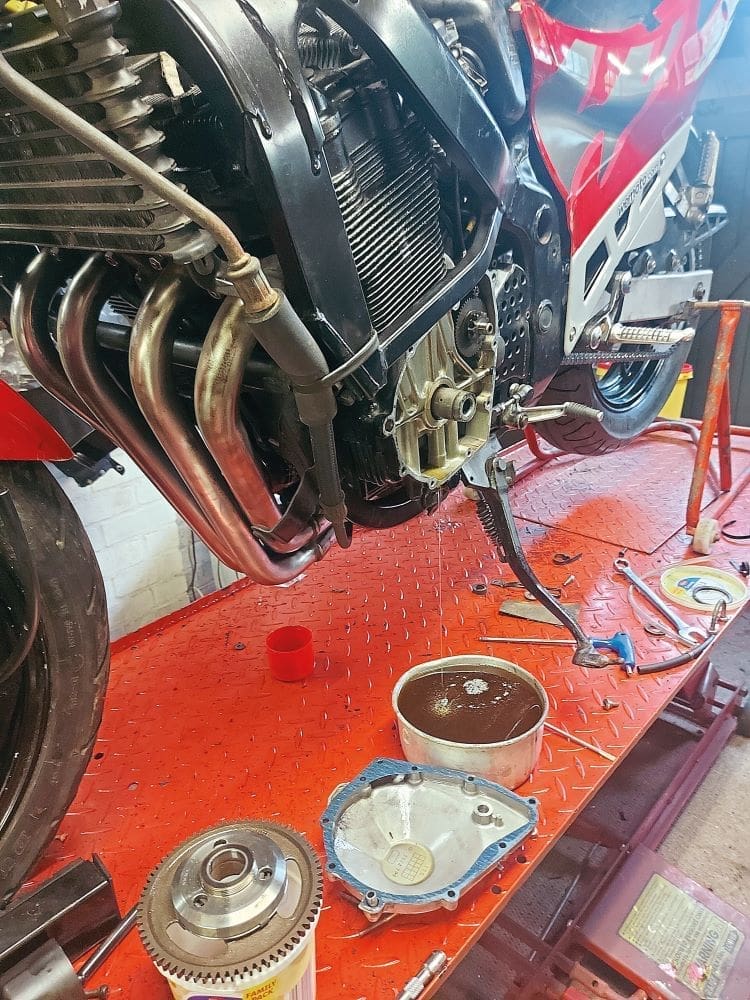

With the exhaust out of the way (and given a clean-up with the grinder and Scotchpad attachment, followed by a brief bit of polishing), and with the aid of a neighbour (thanks Simon!), the motors were swapped over and a rebuild could begin.

I’d previously fitted the alternator and starter motor from the spare engine on to the race bike, but knew that the GSX items would swap straight over, so this was done, but I’d forgotten that I’d removed the starter clutch from the spare, and taken out all the clutch plates, too. I found spares for both, although the clutch pack was one friction plate short (and the clutch in the GSX is different), so a blast down to Sleaford saw an extra couple of plates blagged from Bandit racer Craigo Harris – thanks mate!

While the engines are very closely related, the Bandit is not exactly the same as the GSX. Firstly, the carb spacing is different, although that wouldn’t be a problem as I have a spare set of Bandit carbs (bought with some spare bodywork for the race bike). Also, the engine’s sump is a different profile, and I wasn’t 100% certain that the aftermarket exhaust would fit around the Bandit sump. The spare carbs were found, and cleaned, and in the process I discovered that every float bowl had the drain screw missing. And, of course, it is a different size and thread to the drain screws in the GSX carbs. From Suzuki, the drain plugs are about £25. Each. The caps on the carb balancing spigots also were missing. While wondering how I’d solve those issues, I tried the exhaust to see if it’d fit around the Bandit sump – joy of joys, it did! Although I seemed to have lost the bracket for the end can clamp to pillion peg hanger, so had to make a new one from a small piece of scrap aluminium plate. No doubt the original will mysteriously appear again in a week or so.

Rather than purchase the drain and vacuum plugs from Suzuki, it was cheaper to source another full set of carbs so, after another parts-collecting mission, I had a set of carburettors with all the required parts. But one of the diaphragms in the ‘new’ set was goosed, so it was swapped with a good one from the incomplete carbs, and each carburettor was treated to new main jets, pilot jets, needle air jets and emulsion tubes, all of which I had in my race bike spares stash. Then I discovered that the GSX600F throttle cable wasn’t going to work with the Bandit carbs, as the inner cable was too short and would hold the carb butterflies permanently open. And the Bandit cable is a different fitment at the throttle tube end, having a threaded boss that screws into the switchgear. After some rooting through the Filing Cabinet of Things, I managed to find a cable that would work, albeit a rather long one that would end up being threaded the long way around to the carbs, although I am yet to check that the curved steel tube part of the cable that suits atop the carb linkage actually fits underneath the fuel tank. And then I realised that I was one short of a full set of inlet rubber clamps… why is nothing ever easy? The story of the commissioning of this Nineties Suzuki has most definitely been one of two steps forward and one step back…

I ordered a set of four clamps from the internet, and with them in my grubby hands three days later the carbs slipped – with a little persuasion – into their rightful home and, joy of joys, the airbox slipped on soon after. Approximately 30 minutes later, while looking for a ‘magnet on a stick’, I found a spare carb rubber clamp…

With all in place, I took a closer look at the wiring around the battery, realising that the reason the positive cable was looking a little frayed and stretched was because the wrong battery had been fitted, with the positive and negative terminals being in the wrong place. A battery was ordered (another three days wait), but I progressed by using some jump leads between the battery and the cables. Remote fuel tank plumbed in and the starter button was pressed… whizzzzz…. Bugger, the starter clutch isn’t engaging. I’d forgotten that I’d had this issue with the Bandit, but the starter clutch on the Teapot engine is apparently the same, so I could use that. An hour later, after some choice words and the fabrication of a special tool, the starter clutch was off the 600F engine, and I whipped off the cover on the bike itself. To discover that the bolt that holds the clutch on to the end of the crank hadn’t been tightened up when I’d originally fitted it… aaargh! Note to self – always finish a job before getting distracted by work.

Trying to tighten that bolt to the required torque (140lb-ft), I dropped the bike into gear and placed a steel bar through the back wheel to lock it up. But the clutch seemed to be slipping. Does this never end? Fortunately, that was just down to cable adjustment, and then when all was ready to fire up and check, the battery was flat. With a recharged battery, it still wouldn’t fire, with closer inspection showing no spark at the plugs…

By the time you read this, the event will have been and gone. You’ll find out if the Teapot stayed in one piece in next month’s issue. Or if I set fire to it and used something else. Or if I just gave up and hid under a rock…

Longest Day Challenge

The premise is simple: riding from Land’s End on the morning of the longest day (which in 2024 was June 20 and will be June 21 in 2025.), northwards all the way to John O’Groats, without use of any motorways, and all aboard bikes that cost no more than £600.

In 2024, 35 bikes took part, and over £100k has been raised for Cancer Research UK.

More details about the day can be found here and you can donate to the cause here.